Regular silicon cells were used first until gallium arsenide made it out of r d in the 90s.

Gallium arsenide solar panels cost.

And portable or wearable solar panels could be viable at that cost.

Gallium arsenide in solar cells.

22 the first known operational use of gaas solar cells in space was for the venera 3 mission launched in 1965.

15 conventional 270w solar cells 4 000w 270 14 8 panels and 1m 2 of gallium arsenide cells harvests 220kwh 0 22mwh of energy where a 4m 2 collector cell unit harvests.

While solar technology can be a political football on the ground tossed around and tackled often in space it encounters little.

Like conventional solar panels amorphous solar panels are made from silicon but they are constructed in a different way.

Now efficiency levels top out around 30 for our gallium arsenide solar cells.

It s a compound mixture of gallium and arsenic.

Now almost everything arriving in the ionosphere is multi junction.

Most however top out around 40.

Gallium arsenide gaas has been growing in popularity as a solar panels semiconductor in recent years.

The cost of gallium arsenide solar tech confines its use to space craft.

The approach termed germanium on nothing could enable the cost effective high volume production of pv cells based on iii v materials such as gallium arsenide.

Gallium arsenide is an important semiconductor material for high cost high efficiency solar cells and is used for single crystalline thin film solar cells and for multi junction solar cells.

Why does nasa use solar technology in space.

The silicon layer is exposed appearing like a bottom step.

The amount of radiant light converted to actual electricity is the key.

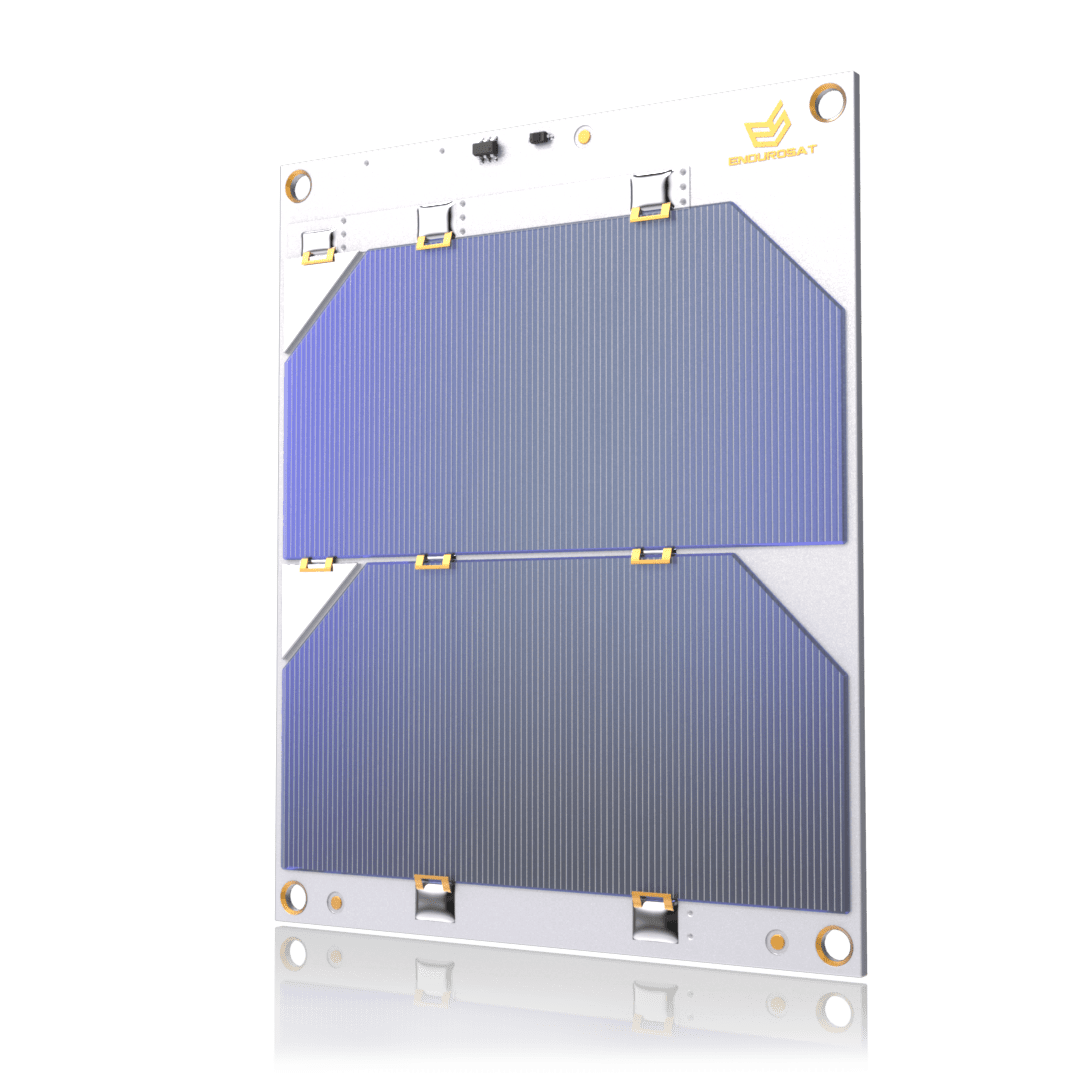

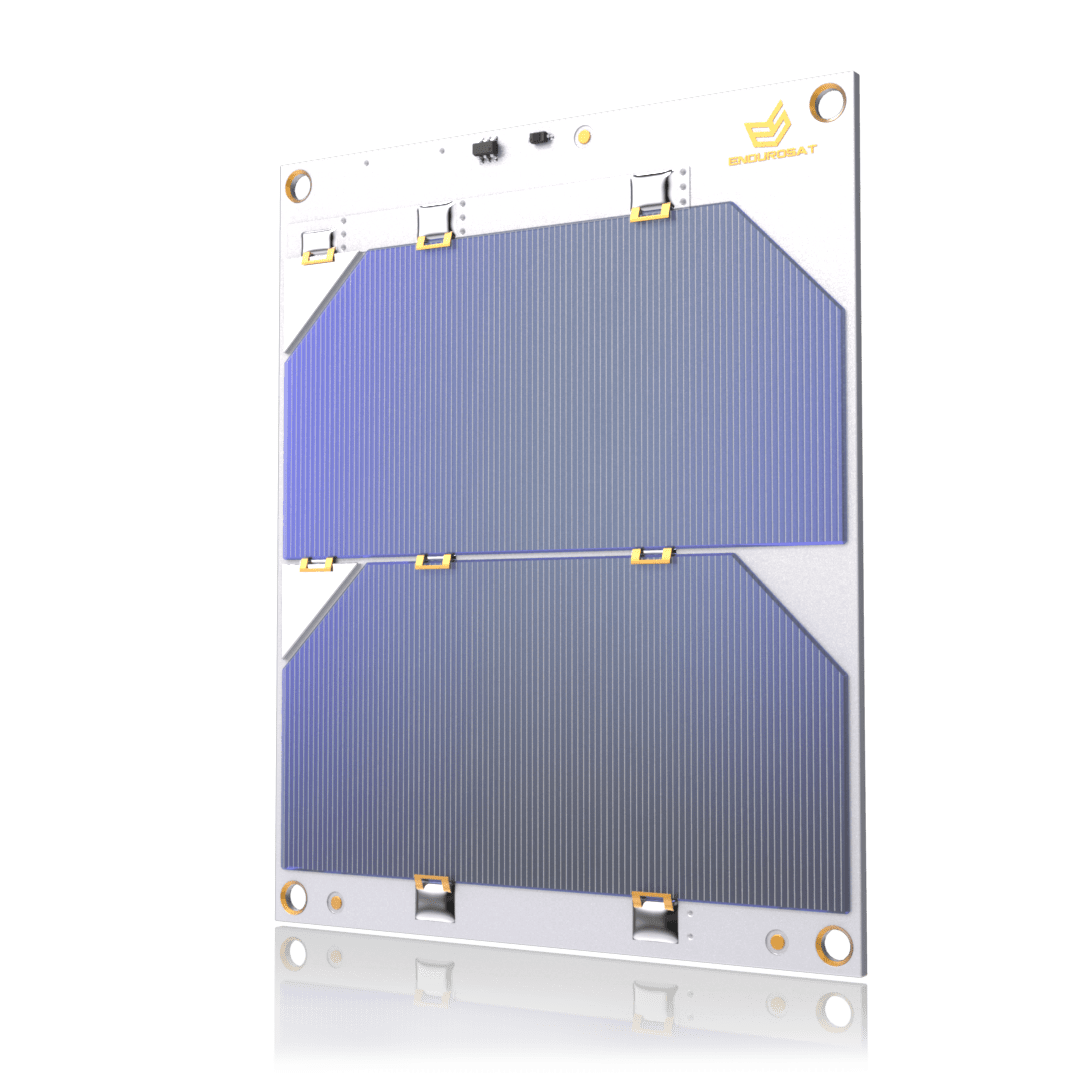

There are two different types of cells being developed using gallium arsenide instead of silicon where two of these 10cm 4 gallium arsenide solar cell replace approx.

It s highly effective as a semiconductor and produces a high energy yield for a small amount of material.

Currently there are a few types of solar cells that can produce a better efficiency rate than that of the gallium arsenide solar cell.

The step cell is made by layering a gallium arsenide phosphide based solar cell consisting of a semiconductor material that absorbs and efficiently converts higher energy photons on a low cost silicon solar cell.

But it can cost about 5 000 to make a wafer of gallium arsenide 8 inches in diameter versus 5 for a silicon wafer according to aneesh nainani who teaches semiconductor manufacturing at.