Corning gorilla tm glass an alumino silicate thin sheet glass produced by corning s proprietary fusion forming technology is designed to provide users with a durable glass substrate ideal for use in applications where high strength and damage resistance is required.

Gorilla glass 3 product information sheet.

Applications ideal for protective covers for electronic displays in.

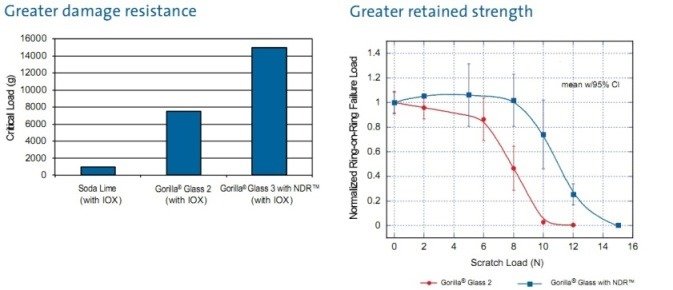

0 2000 4000 6000 8000 soda lime no iox soda lime with iox gorilla with iox c r i t i c a l o l o a d g it takes more load to initiate radial cracks in the glass.

Enables use of thinner glass.

With its new core composition this glass enables improved damage resistance and toughness by helping to prevent the deep chips and scratches that cause glass to break.

In our lab tests highly damage resistant gorilla glass 3 provides up to a 4x improvement in scratch resistance when compared to competitive aluminosilicate glasses from other manufacturers.

Corning gorilla glass 4 up to 1 5x up to 1 8x incremental face drop on 180 grit sandpaper corning puck 0 0 0 2 0 4 0 6 0 8 1 0 1 2 chemical strengthening time compressive stress depth of compression ormance corning gorilla glass 5 corning gorilla glass 4 results may be varied by thickness and chemical strengthening recipe similar.

0 20 40 60 80 100 120 140 160 0 3 0 5 0 7 0 9 1 1 1 3.

Corning gorilla glass 3 with native damage resistance is an alkali aluminosilicate thin sheet glass that is better able to survive the real world events that most commonly cause glass failure.